TST Sweden AB

Body Temperature Control Vest "Cooling Vest"

Body Temperature Control Vest made using coolant PCM. Cooling boxes and electricity costs are unnecessary.

The "Cooling Vest" of TST Sweden AB

The Swedish manufacturer TST Sweden AB was founded in 1990. TST Sweden AB uses unique and revolutionary technology to develop and manufacture a variety of high-function, high-comfort protective clothing. The company's "Cooling Vest", a body temperature control vest, uses as coolant the special PCM (Phase Changing Material. Changes from a solid into a jelly at temperature of 28℃ and higher. During the change, body heat is absorbed, preventing increases in body temperature). Unlike refrigerants and cold sprays, cooling boxes and electricity costs are not necessary. Furthermore, the vest provides cooling which is gentle for the wearer's body, without overcooling. The Cooling Vest is ideal for wearing under heat-resistant clothing, fire-resistant clothing, and chemical protective clothing which protects the user from chemical and viral bacteria, as well as under work clothing worn in manufacturing facilities, factories, and other severe high-temperature work environments (high temperature work environments where air conditioning is not possible). In such environments, the vest protects the wearer from heat stress and contributes to increased work efficiency. Also, the vest increases concentration ability during work, thus contributing to the safety of the wearer.

Functions of the Cooling Vest

The Cooling Vest is a body temperature control vest that was developed to protect the wearer from increases in body temperature during work in high-temperature environments and during other extreme activities. A total of 22 units of PCM (Phase Change Material. PCM is not refrigerant or cooling spray.) are inserted into the pockets on the inside of the vest. This PCM absorbs heat from the body of the wearer.

*The reason that PCM cools even though it is not a coolant.

Water possesses the phases of gas (water vapor/steam), liquid (water), and solid (ice). Water requires great energy (emission) when changing between these phases. PCM has characteristics which are similar to water, changing phases from a solid to a liquid at 28℃ (water changes phases at 0℃). During this phase change, PCM absorbs a great amount of energy, thus preventing temperature increases in the surrounding area.

Main Features of the Cooling Vest

- Simple storage/restoration without the need for a cooling box.

- Simple storage/restoration without the need for a cooling box. PCM is restored from a liquid (jelly) to a solid at temperatures of 22℃ and lower. Therefore, there is no need to carry a cooling box. Also, electricity costs are not incurred. In almost all cases, the PCM naturally returns to the original solid state simply by being stored when not in use. Even when used in high-temperature environments, restoration can be performed simply by placing the PCM in an air-conditioned room (22℃ and lower). Approximately 2 to 3 hours are required for restoration when the PCM is placed in an area with an external air temperature of 22℃. Although a freezer or refrigerator is not normally needed, it is possible to place the PCM in a freezer or refrigerator when it is desired to decrease the time required for restoration. Approximately 30 minutes are required for restoration in a refrigerator with a temperature of 8℃, while approximately 15 minutes are required for restoration when a freezer is used.

- Cooling that is gentle to the body

- Excessive heat is taken from the user through the use of refrigerants, cooling sprays, and other coolants which are stored in a cooling box. In some cases, use of these coolants can cause ailments such as diarrhea, abdominal pain, frostbite, or decreased physical functionality. PCM, which operates (changes phases) at 28℃, is not excessively cold and can be worn over clothing such as a thin T-shirt. PCM is a coolant that was developed by considering the health and comfort of the worker.

- Cooling effect last for long periods

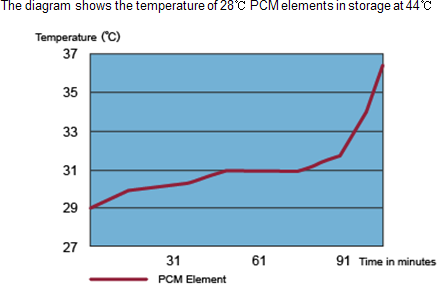

- The cooling effect is sustained until the PCM reaches a jelly state (approximately 45 minutes to 2 hours). The advantage is that a cooling effect is received only when needed by the body.

- Comfortable to wear

- The Cooling Vest is easy to put on and its simple design fits snuggly to the body of the wearer. At approximately 2 kilograms, the vest is lightweight and does not interfere with movement when worn under clothing such as chemical protective clothing or fire-resistant clothing.

*In order to achieve maximum functionality and comfort, the Cooling Vest should be worn over thin clothing that allows moisture to pass.

Example uses of the Cooling Vest

・Wear under chemical protective clothing, fire-resistant clothing, heat-resistant clothing, insulating clothing, work clothing, sports wear, or other apparel.

Processing of hazardous materials, processing during special disasters, fire fighting, rescue, nuclear power plant, thermal power plant, factories such as iron factories (smelting furnace, welding, boiler, etc.), motor sports (race driver, mechanic), various sports (the vest is used in Sweden by the national ski team as part of their cool-down), etc.

Reference Data

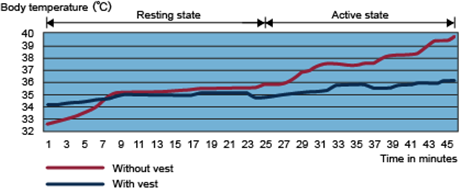

Effects of the Cooling Vest (experiment results)

The test was performed using 2 firefighters who were dressed for smoke diving with breathing masks on. They stayed in 55℃ heat, for first 25 minutes without physical exertion, after which the workload was increased.

防護レベル

黄色:直射ジェットで1,000bar、回転ジェットで2,800barの防護レベルを示す。

オレンジ:直射ジェットで2,000bar、回転ジェットで3,000barの防護レベルを示す。